17 + YEARS OF

EXPERIENCE

1500 + SATISFIED

CUSTOMERS

1 + OWNED OFFICE

IN INDIA

10 + DEDICATED

ENGINEERS

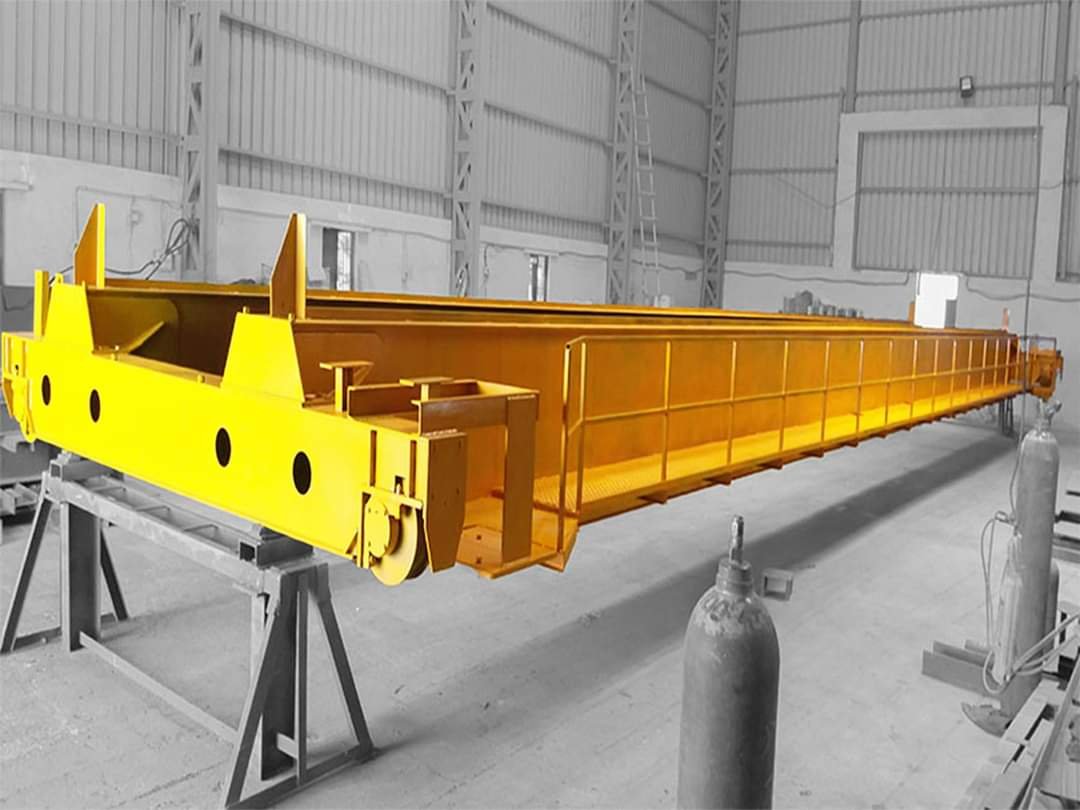

EOT CRANES are used to lift the load. Double girder EOT cranes are widely used for heavy load lifting in many industries. The extent of the Eot Crane is high and there is a good stand, by which cranes are repaired with the non-functioning situation.

FEATURES & SPECIFICATIONS

Standard Features &

Specifications of EOT

Cranes

Range Available :

- 1 Ton Capacity Double Girder Cranes

- 2 Ton Capacity Double Girder Cranes

- 5 Ton Capacity Double Girder Cranes

- 7.5 Ton Capacity Double Girder Cranes

- 10 Ton Capacity Double Girder Cranes

- 12.5 Ton Capacity Double Girder Cranes

- 15 Ton Capacity Double Girder Cranes

Range of Specification

- There is workload from 500kgs to 20000kgs.

- Its span is 5meters to 75 meters.

- Indian Standard (IS: 3177, IS: 3938, IS: 4137, IS: 15419, IS: 807, IS: 800)

- Breaks suitable for cross travel and long travel.

- Control panel with facility of radio remote control and pendant push buttons.

Maintenance Platform with Hand Railing :

- Easy, simple & safe maintenance of the Crane extended partially or along the full length of the girder.

- Soft Starts: Electric / Electronic soft start modules electrically drive to achieve jerk free smooth starts.

- Painting: Each & every component & spare part are completely scrubbed & painted with suitable primer and paint.

Electrical Panel :

- There is transmission wiring designed and easy to install and keep in the act.

- Better design, easy in installation and maintenance, reliable operation, dustproof with standard quality.

- Overload relay for Motor safety.

Limit Switch :

- Limit switching to prevent from over traveling.

- Maximum stability due to double girder box design.

- Geometrically reliable during assembly owing to bolted design.

- Multiple speed selection options for all motions using VVVF Drive

- Ideal for the operator to use optional cabin control.

Types of Cranes :

- Lattice type EOT crane capacity to lift loads up to three mt.

- Box type semi gantry cranes, capacity having 5 Mt.

- Lattice type gantry cranes have 10 Mt. capacities.

- Lattice type Goliath crane with one side overhang.

- NK Engineering provides various types of double girder EOT crane depending on

their sizes and capacities of lifting load. - They have a collection of 2 tons EOT cranes to 50 tons EOT cranes.

Areas of Using Eot Crane:

Benefits of EOT Crane :

- For industries and construction sites, EOT cranes are crucial pieces of equipment.

- They make it easier to carry heavy objects, which can save time and energy.

- You don’t have to spend hours trying to manually move large objects because EOT cranes can move them swiftly.

- You’ll be able to concentrate on other chores because you’ll have saved time and effort.

- Additionally, it lessens lifting and carrying large objects-related fatigue.

Basic Information :

- When we apply crane for our use we should have the knowledge regarding it. The crane is a device used for lifting heavy loads in big industries and mills, which makes your work effortless. You do not need to spend much labour on your work. There are different types of double girders that save your time, money, and energy.

- EOT Crane reduces labour costs and manpower and it works swiftly and smartly.

Why to Choose NK Engineering :

- It provides services to domestic and global companies.

- Having a good potential sales and services system.

- They have a properly furnished office and tools depot.

- The Sales operation system is maintained by experienced and qualified Technicians.

- 24*7*365 days Support.

Work With Us

How to Choose the Right EOT Crane?

Before Buying an EOT Crane, Consider These Factors:

- Load Capacity – Choose a crane that can handle your heaviest load.

- Lifting Height – Ensure it fits your factory or warehouse requirements.

- Span Length – Measure the distance the crane needs to cover.

- Speed & Control System – Opt for variable-speed hoists for precision lifting.

- Safety Features – Look for overload protection, emergency stop, and remote control.

Pro Tip: Always buy from a trusted EOT crane manufacturer with ISO-certified products and after-sales support.

Why is EOT Crane Maintenance Important?

Benefits of Regular EOT Crane Maintenance:

- Prevents Unexpected Breakdowns – Regular checks ensure that small issues don’t turn into major failures.

- Enhances Workplace Safety – Reduces the risk of accidents caused by loose wires, faulty brakes, or overloading.

- Improves Performance & Efficiency – Well-maintained cranes operate smoothly and with precision.

- Increases Lifespan – With proper care, an EOT crane can function without major issues for decades.

- Ensures Compliance with Safety Standards – Helps meet Indian safety regulations like IS 3177 & IS 807.

Pro Tip: Many companies lose up to ₹10-50 lakh annually due to unexpected crane failures. Regular maintenance can prevent such losses!

Frequently Asked Questions

An EOT (Electric Overhead Traveling) crane is a type of crane that operates on tracks mounted on the ceiling or elevated beams. It’s commonly used in factories and construction sites to lift and move heavy loads horizontally.

An electric wire rope is a strong and flexible cable made of wire strands twisted together. It’s a vital component in various lifting equipment, including cranes and hoists, providing the necessary strength and durability for lifting heavy loads.

A Flame Proof hoist is designed to operate safely in environments with potentially explosive gases or dust. It’s a crucial tool in industries like petrochemicals, mining, and oil refineries where safety is paramount

Yes, there are several EOT crane manufacturers in India. These companies design, produce, and supply a wide range of EOT cranes to cater to the industrial needs of the country.

A gantry crane is used to lift and move heavy loads within a confined area. It’s often seen in shipping yards, construction sites, and manufacturing facilities for tasks such as loading and unloading containers.

A jib crane has a horizontal arm (jib) that extends from a vertical mast. It’s used for precise lifting and positioning tasks, such as moving materials in workshops or loading docks.

When choosing a crane manufacturer in India, consider factors such as their experience, reputation, product quality, after-sales service, and adherence to safety standards. It’s essential to partner with a reliable manufacturer to ensure your lifting equipment meets your requirements and safety regulations.