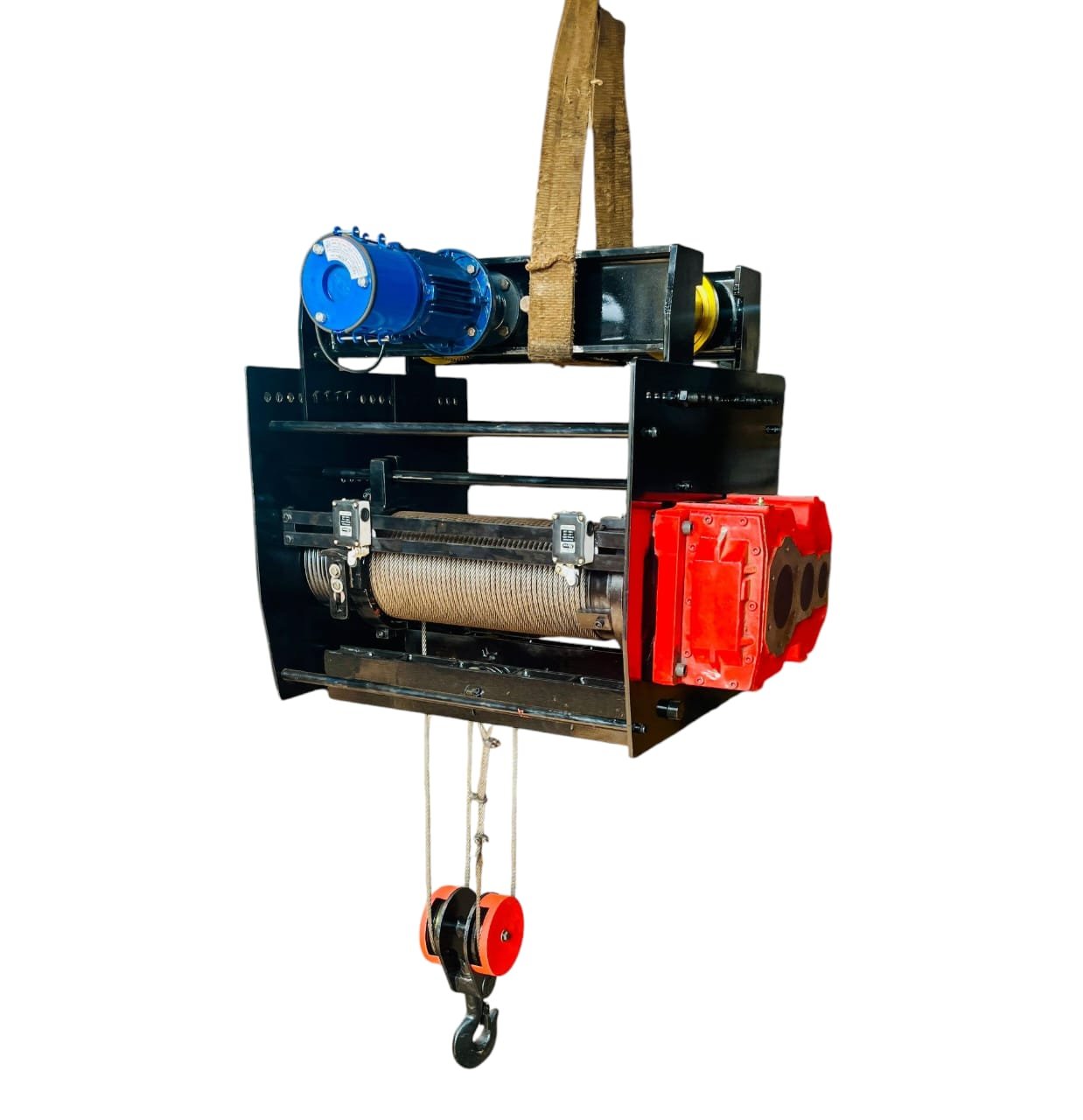

Hoist

17 + YEARS OF

1500 + SATISFIED

1 + OWNED OFFICE

10 + DEDICATED

India’s Trusted Hoist Crane Experts

Why Hoists are Important for Lifting Equipment?

An Electronic hoist is user friendly for lifting heavy machines or loads. That is why it is capable to lift and convey heavy items and loads without effort and swiftly. Hoists are able to shift loads restfully and dynamically & it helps you to save your time and cost.

Advantages of Hoists:

- Improves Productivity: – An electronic hoist does your work conveniently and easily compared to other types of cranes. It does work in a short period. It boosts your productivity.

- Enables to Heavy Load: – It has usually a high combined hoist and trolley conjunction. It empowers you to lift easily high range of loads and it will improve machines efficiency.

- Cost Potential: – Labor is not used much by the reason of machines good ability to lifting load makes it cost effective.

- Flexibility: – It gives you extra flexibility for your work type & helps you with multipurpose. So, that your work becomes easy & cost effective. Hoists will rotate vertically as well as pull the load sideways.

- Decreases Noise Pollution: – This type of machine makes low noise compared to other types of hoists. It is good for your health if you have continuously worked with hoists because it generates low noise.

- More Longevity: – If you maintain the hoists properly then they will use many years after you had purchased.

Benefits of Hoists:

- It saves time and capital

- It minimizes risks and injury costs.

- It boosts up staff moral and keeps them energetic at the end of shift.

- It is simple to use at any time.

- There is a low maintenance cost because of modular design.

Standard Features of Hoists:

- Load blocks: – There is an eyehook, clevis hook, or special convention to lift a heavy load.

- Wire rope: – Metal strands designed for long durability.

- Wire rope drum: – It has deep grooving and fast disconnect power to dead-ending.

- Drum shaft: – It is manufactured from high strength and cold rolled steel.

- Motor: – There are thermal switches contained to save from overloading the motor.

- Motor-break: – It is electrically managed and spring applied.

- Gear decreases: – Speed is reduced by gear rotationally.

Specification Guide of Hoists:

An Electronic hoist is user friendly for lifting heavy machines or loads. That is why it is capable to lift and conveying heavy items and loads without effort and swiftly. Hoists are able to shift loads restfully and dynamically & it helps you to save your time and cost.

- Type of Hoist: – First, you have to select the proper hoist depending on your work type.

- Hoist Specification: – lift speed, capacity and voltage required are considered.

- Period of work: – Days and hours used should considered.

- Atmosphere of work site: – Range of temperature and indoor or outdoor environment suitable are kept in mind.

Types of Hoists Provided by NK Engineering :

- Manual push-pull trolley type

- Long chain working trolley type

- Motor driven trolley type

- Radio remote control type

Why to Choose NK Engineering.

- It provides services to domestic and global companies.

- Having a good potential sales and services system.

- We have a proper furnished office and tools depot.

- The Sales operation system is maintained by experienced and qualified technicians.

- 24*7*365 days Support.

Work With Us

How to Choose the Right Hoist Crane for Your Industry?

When Selecting a Hoist Crane, Keep These Key Factors in Mind:

- Load Capacity – Ensure the crane meets your maximum weight requirements.

- Lifting Height – Choose a model that fits your facility’s vertical space.

- Type of Hoist – Chain hoists for lighter loads; wire rope hoists for heavy-duty applications.

- Speed & Efficiency – Opt for VFD-controlled hoists for better speed control.

- Durability & Safety Features – Look for emergency brakes, overload limiters, and heat-resistant motors.

- Brand & Warranty – Always buy from a reputed manufacturer with good after-sales support.

Fact: In India, using the right type of hoist crane can increase factory efficiency by 30% while reducing manual labor costs.

Maintenance Tips for Hoist Cranes

To Ensure Long-Term Efficiency and Safety, Regular Maintenance of a Hoist Crane is Essential. Here’s a Quick Checklist:

- Daily Inspection – Check for wear and tear on the wire rope or chain.

- Lubrication – Apply grease or oil to prevent friction and overheating.

- Load Testing – Conduct periodic load tests to verify lifting capacity.

- Electrical System Check – Inspect control panels, wiring, and limit switches.

- Brake Testing – Ensure that emergency brakes function properly.

Fact: Regular hoist crane maintenance can increase equipment lifespan by up to 50% and prevent sudden breakdowns.

Why Invest in a Hoist Crane?

A Hoist Crane is an Essential Investment for Businesses that Handle Heavy Loads Daily. Here’s Why It’s a Game-Changer:

- Reduces Human Effort – Minimizes manual labor and speeds up operations.

- Improves Workplace Safety – Lowers the risk of lifting-related accidents.

- Boosts Productivity – Enhances workflow efficiency with faster lifting.

- Cost-Effective Solution – Saves money on labor, downtime, and material damage.

- Long-Term Investment – A well-maintained hoist crane lasts 15-20 years, offering high ROI.

Pro Tip: If you want a durable and cost-effective hoist crane, always choose one with ISO and ISI certifications to ensure safety and reliability.

Frequently Asked Questions

An EOT (Electric Overhead Traveling) crane is a type of crane that operates on tracks mounted on the ceiling or elevated beams. It’s commonly used in factories and construction sites to lift and move heavy loads horizontally.

An electric wire rope is a strong and flexible cable made of wire strands twisted together. It’s a vital component in various lifting equipment, including cranes and hoists, providing the necessary strength and durability for lifting heavy loads.

A Flame Proof hoist is designed to operate safely in environments with potentially explosive gases or dust. It’s a crucial tool in industries like petrochemicals, mining, and oil refineries where safety is paramount

Yes, there are several EOT crane manufacturers in India. These companies design, produce, and supply a wide range of EOT cranes to cater to the industrial needs of the country.

A gantry crane is used to lift and move heavy loads within a confined area. It’s often seen in shipping yards, construction sites, and manufacturing facilities for tasks such as loading and unloading containers.

A jib crane has a horizontal arm (jib) that extends from a vertical mast. It’s used for precise lifting and positioning tasks, such as moving materials in workshops or loading docks.

When choosing a crane manufacturer in India, consider factors such as their experience, reputation, product quality, after-sales service, and adherence to safety standards. It’s essential to partner with a reliable manufacturer to ensure your lifting equipment meets your requirements and safety regulations.